Tightness, safety and durability are always at the forefront in industrial flow control systems. Especially valves used in high pressure and large diameter pipelines play a critical role in the efficient operation of the system. One of the prominent solutions at this point is trunnion ball valves. So, what is a trunnion type ball valve and what advantages does it offer? We discuss it in detail in this article.

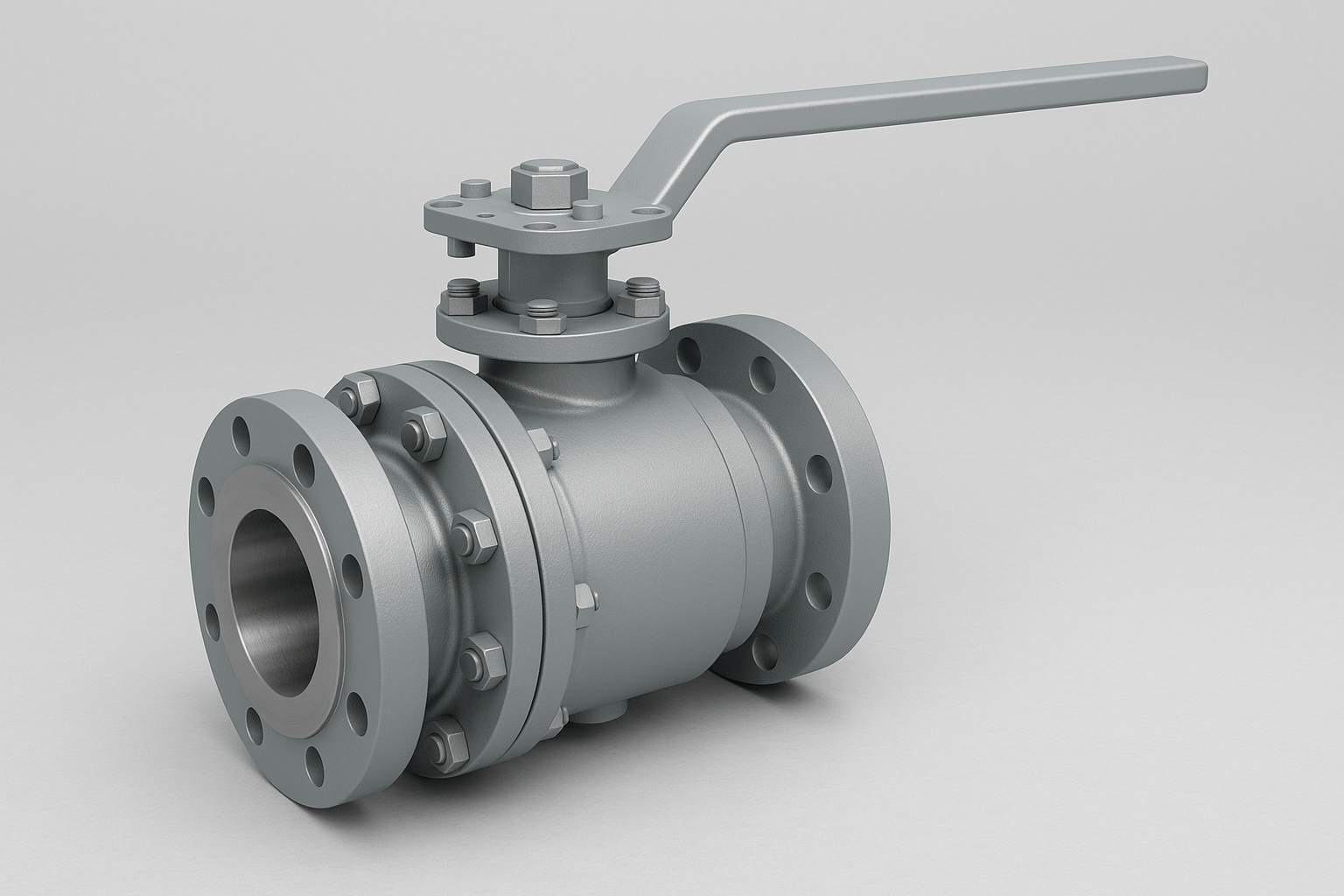

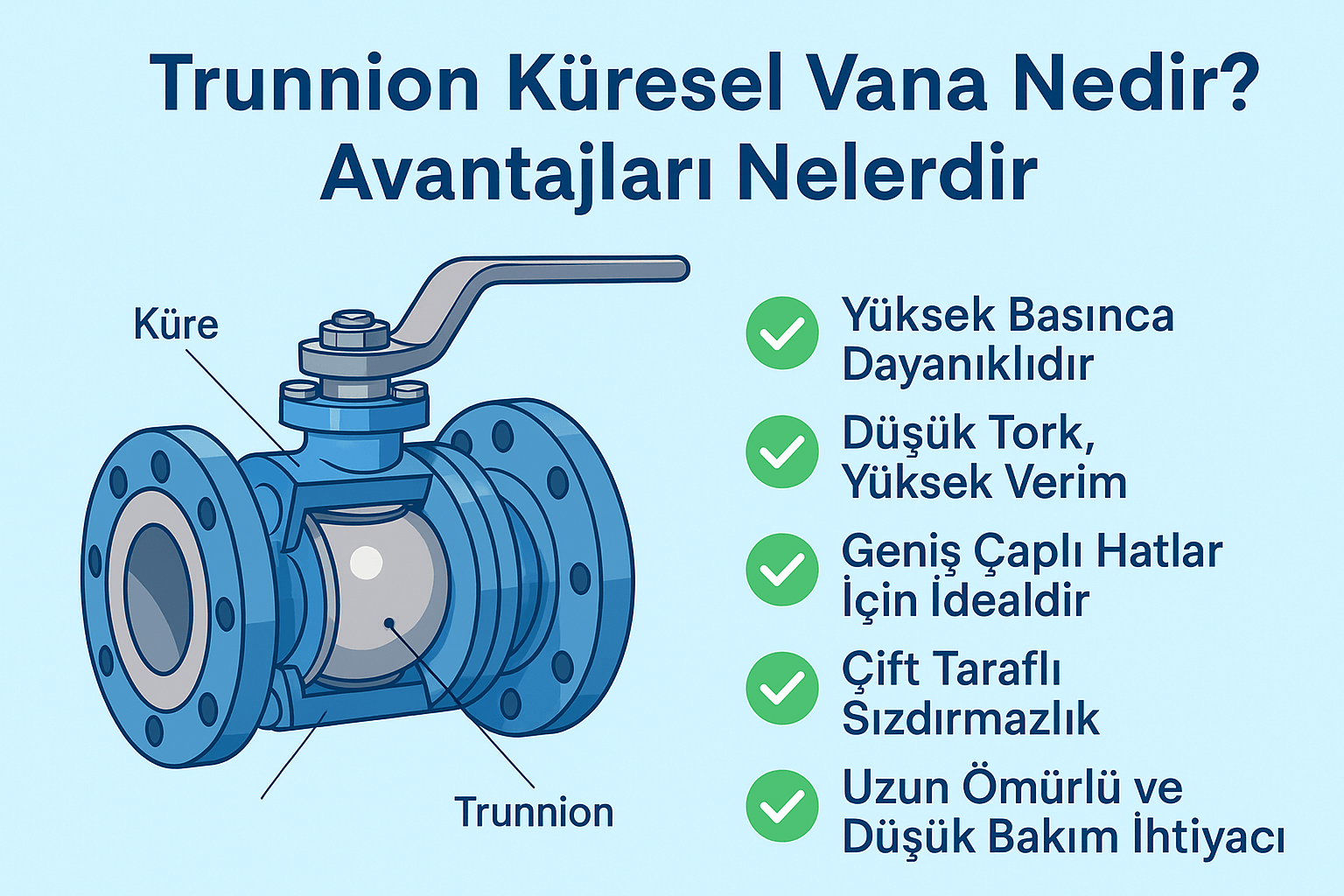

What is a Trunnion Ball Valve?

A trunnion ball valve is a special type of ball valve that has a rotating sphere inside and this sphere is supported on both sides. These support points are called “trunnions”. Unlike standard floating ball valves, in trunnion type valves the sphere is fixed from above and below with supports fixed to the body. Thus, the sphere makes only rotational movement and no axial movement.

Thanks to this structure, it can work with lower torque even under high pressure, providing a more secure seal with less energy.

How does it work?

Trunnion ball valves keep the sphere on a fixed axis thanks to the support spikes in its internal structure. The pressure generated by the fluid is transmitted to the trunnion supports , not directly to the sealing gaskets. In this way:

-

Sealing elements fatigue less,

-

Torque requirement is reduced,

-

A more secure structure is formed against high pressure.

Advantages of Trunnion Ball Valve

1. Resistant to High Pressure

Trunnion structure provides a safe and stable flow control especially in high pressure lines. There is no decrease in valve performance as the pressure increases.

2. Low Torque, High Efficiency

It operates with lower torque than standard ball valves. This means advantages in terms of actuator selection and energy consumption.

3. Ideal for Large Diameter Lines

It is one of the most reliable solutions in DN150 and above diameters, especially in oil, natural gas, water and energy lines.

4. Double Side Sealing

Thanks to the two-way sealing gaskets, flow can be safely controlled from both directions.

5. Long Life and Low Maintenance

The seals wear less because the ball movement is stabilized. This means low maintenance costs for long-term use.

In which sectors is it used?

Trunnion ball valves are widely preferred in the following sectors:

-

🛢️ Oil and gas transmission lines

-

🔥 Natural gas pressure reduction stations

-

⚙️ Power plants

-

💧 Water transmission and distribution systems

-

🏭 Chemical and petrochemical plants

Why Trunnion Valve Preferred?

While standard ball valves provide ideal performance in specific pressure ranges, trunnion type valves stand out in environments that require consistently high performance. From a long-term investment and system safety perspective, these valves are like a safety lock on the line.

ContactUs

When choosing a Trunnion ball valve, it is necessary to correctly determine many technical details such as material, diameter, pressure class and torque calculations. As Valve.tr, we provide technical support for you to choose the right valve type. If you want to get information about our project-specific solutions, especially in high pressure applications, you can contact us.

Final Evaluation

Trunnion ball valves are an indispensable part of industrial systems in terms of safety, performance and long life. The ability to operate with low torque and double-sided sealing features, especially in heavy-duty applications, make these valves one step ahead. To choose the most suitable valve for your system, you should analyze your technical needs well and secure your investment by getting expert support if necessary.